Um series five axis double column machining center is widely used in precision machining of aerospace, automobile mold, complex curved surface and other industries.

The main body is designed with a high rigidity double column structure, and the base casting is treated by three times of aging to ensure the long-term stability of mechanical accuracy.

Both B and C rotating axes are equipped with absolute grating scales, which run smoothly and ensure he accuracy of machine positioning and repeatability.

The B and C axes of the swing head are driven by direct drive motors, with high speed, high response, non-backlash, and never wear.

Five axis anti-collision function as standard, the response time is less than 10ms, which can effectively protect tools, workpieces and equipment.

|

Items

|

Unit

|

UM2318

|

UM3218

|

UM4118

|

|

Standard controller

|

|

FANUC 0i—MF plus absolute type 0 15"LCD

|

|

Travel

|

X axis travel (work-table)

|

mm

|

2300

|

3200

|

4100

|

|

Y axis travel (saddle)

|

mm

|

2500

|

|

Z axis travel (spindle head)

|

mm

|

1000

|

|

Rotation angle

|

B axis

|

|

±110°

|

|

C axis

|

|

±360°

|

|

Work table

|

Table size (length×width)

|

mm

|

2300X1600

|

3200X1600

|

4100x1600

|

|

Spindle

|

Spindle taper

|

|

HSK-A63

|

|

Max. spindle speed

|

rpm

|

16000(Build-in)

|

|

Spindle motor power(continual working)

|

kW

|

25

|

|

Spindle torque

|

N.m

|

66.5

|

|

Machine size (length/width/height)

|

mm

|

7366x4933x5510

|

9066x4933x5510

|

10466x4933x5510

|

|

Machine weight

|

kg

|

29000

|

32000

|

35000

|

We reserve the right to change technical parameters for improvement of our products without giving notice to customers.

|

|

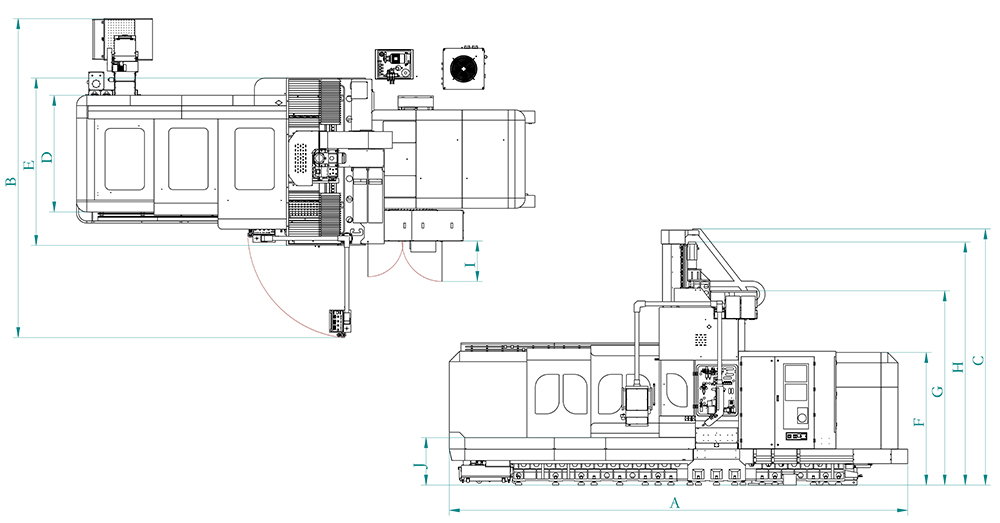

A

|

B

|

C

|

D

|

E

|

F

|

G

|

H

|

I

|

J

|

|

UM2318

|

7366

|

5600

|

5510

|

2639

|

4525

|

2509

|

3447

|

4404

|

790

|

940

|

|

UM3218

|

9066

|

5600

|

5510

|

2639

|

4525

|

2509

|

3447

|

4404

|

790

|

940

|

|

UM4118

|

10466

|

5600

|

5510

|

2639

|

4525

|

2509

|

3447

|

4404

|

790

|

940

|

|

UM2322

|

7366

|

6000

|

5510

|

3039

|

4925

|

2509

|

3447

|

4404

|

790

|

940

|

|

UM3222

|

9066

|

6000

|

5510

|

3039

|

4925

|

2509

|

3447

|

4404

|

790

|

940

|

|

UM4122

|

10466

|

6000

|

5510

|

3039

|

4925

|

2509

|

3447

|

4404

|

790

|

940

|

We reserve the right to change technical parameters for improvement of our products without giving notice to customers.